MagnaCut, a novel stainless steel variant, is rapidly garnering recognition and favor among aficionados of knives. The material in question is classified as a powder metallurgy (CPM) steel, denoting its manufacturing process involving the consolidation of metal powders by sintering at high temperatures and pressures. The aforementioned procedure yields a steel of high density and uniformity, exhibiting exceptional characteristics.

One of the primary benefits associated with MagnaCut is its notable capacity for maintaining a sharp cutting edge over an extended period of time. The durability of this knife’s sharpness surpasses that of conventional stainless steel blades, exhibiting little wear even under extensive use. The presence of a significant quantity of finely dispersed carbides inside MagnaCut’s microstructure is responsible for this phenomenon.

One additional benefit of MagnaCut is its exceptional durability. The material has a high level of resistance to both chipping and breaking, even when used in slender blade configurations. This characteristic renders it a favorable option for a diverse range of knife categories, including kitchen knives, pocket knives, and outdoor knives.

Additionally, MagnaCut has a high level of resistance to corrosion. The material has the capability to endure prolonged contact with moisture and saltwater, exhibiting resistance to rusting or corrosion. This characteristic renders it a favorable option for use in maritime settings or for blades that are often subjected to moist circumstances.

What factors contribute to the increasing popularity of MagnaCut?

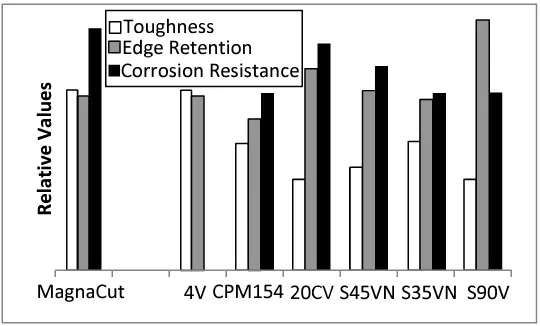

There are several factors contributing to the increasing popularity of MagnaCut. Initially, the steel in question exhibits remarkable versatility, making it suitable for a diverse range of knife applications. Furthermore, the product has exceptional performance across three fundamental aspects, namely edge retention, toughness, and corrosion resistance. Moreover, the process of sharpening and maintaining it is extremely straightforward.

MagnaCut vs. Other Premium Knife Steels

MagnaCut is often subjected to comparative analysis with other high-quality knife steels, such as Maxamet, Elmax, and S90V. Although each of these steels demonstrates exceptional performance, there exist notable distinctions among them.

Maxamet is well recognized for its exceptional ability to maintain a sharp cutting edge over extended periods of use. This particular knife steel exhibits superior edge retention compared to all other available options on the market. Nevertheless, it is worth noting that this particular steel has a high degree of hardness, hence making the sharpening process somewhat challenging.

Elmax steel is widely regarded as a very versatile material that exhibits exceptional properties in terms of edge retention, hardness, and resistance to corrosion. Furthermore, the process of sharpening is pretty straightforward.

S90V is a steel known for its exceptional hardness, as well as its remarkable ability to maintain a sharp cutting edge and resist wear over time. Nevertheless, it is worth noting that this particular steel presents the most challenge when it comes to the sharpening process among the four types mentioned.

What are the future prospects for MagnaCut?

MagnaCut, while steel of recent introduction, is seeing a rapid surge in popularity among the community of knife lovers and knife makers. With increasing awareness among individuals about its exceptional characteristics, it is anticipated that its popularity will further escalate in the future.

Meta Trend of Premium Knife Steel

The inclusion of MagnaCut on the market reflects a broader movement towards the use of high-quality knife steels. There is a growing trend among knife lovers to seek knives constructed from high-performance steels that provide superior qualities in terms of edge holding, hardness, and resistance to corrosion. The aforementioned phenomenon may be attributed to several variables, such as the escalating appeal of outdoor pursuits, the surging viewership of culinary programs, and the expanding accessibility to superior knife alloys.

Some of the currently popular varieties of premium knife steel include:

Maxamet

Maxamet is a steel alloy known for its exceptional hardness and superior ability to maintain its cutting edge over extended periods of use. Frequently used in the manufacturing of premium culinary knives and outdoor knives.

Elmax

Elmax steel is widely regarded as a versatile material due to its commendable attributes, including exceptional edge retention, robustness, and resistance to corrosion. Moreover, the process of sharpening is pretty straightforward.

S90V

90V is a very durable steel known for its exceptional ability to maintain a sharp edge and resist wear. Frequently used in the manufacturing of premium-grade folding knives and outdoor blades.

Conclusion

MagnaCut is a novel stainless steel variant that demonstrates exceptional performance in three fundamental domains: edge retention, toughness, and corrosion resistance. The steel in question exhibits a high degree of versatility, rendering it suitable for a diverse range of knife applications. Furthermore, it has the advantageous characteristic of being reasonably straightforward to sharpen and upkeep. With increasing awareness of its exceptional characteristics, it is anticipated that its popularity will further escalate in the next years.

Additional Thoughts

- The MagnaCut is a relatively brand-new invention, yet has been adopted by some of the best knife makers. This underscores its superior qualities and its potential as the first modern blade industry revolutionizing factor.

- Several driving forces behind this premium knife steel meta trend consist of the growing interest in outdoor activities, an upward surge in cooking shows, and finally, easy accessibility of high-end knife steels. With the increasing exposure of people to high-performance knives, it is probable that the demand for top-grade knife steels will also increase.

- For instance, the use of technology in improving the performance of knives can be illustrated through an example like MagnaCut. The new steelmaking processes combined with growing data are making it possible for makers to develop steels with exceptional characteristics, that no one has ever seen before.